Tips for selecting eye washers (1)

Views:547 ClassificationCorporate News ClassificationIndustry news Classificationnews

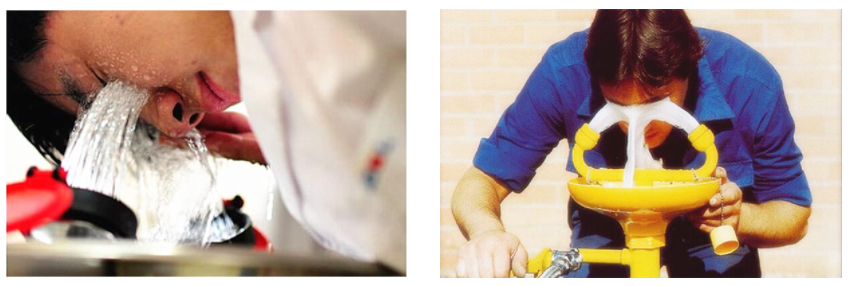

Eye washers are used in emergencies when toxic and harmful substances (such as chemical liquids, etc.) splash the body, face and eyes of staff or fire causes clothing fire of staff to temporarily slow down the further damage of harmful substances to the body. Further treatment and treatment should follow the guidance of doctors to avoid or reduce unnecessary accidents.

As early as in the 1980s, eye washers were widely used in most factories, laboratories and hospitals in foreign developed industrial countries (USA, UK, etc.). Its purpose is to reduce the harm to the body caused by toxic and harmful substances in the work. It is widely used in petroleum, chemical industry, semiconductor industry, pharmaceutical manufacturing industry and places where dangerous substances are exposed.

So how to choose the right eye wash product?

First: according to the work site toxic and harmful chemicals to decide

In the presence of chloride, fluoride, sulfuric acid or oxalic acid with a concentration of more than 50%, only ABS impregnated stainless steel eye wash or specially treated high performance stainless steel eye wash can be selected. Because the eye washer made of 304 stainless steel can resist the corrosion of acid, alkali, salt and oil under normal circumstances, but cannot resist the corrosion of chloride, fluoride, sulfuric acid or oxalic acid with a concentration of more than 50%. In the working environment where the above substances exist, the eye washer made of 304 stainless steel can be used in less than six months. The eye wash will have a great deal of damage. The concept of ABS immersion and ABS spraying is different. ABS immersion is ABS powder immersion, rather than ABS liquid immersion.

1. ABS powder immersion features :ABS powder adhesion strength is strong, the thickness of 250-300 microns, strong corrosion resistance.

2. ABS liquid immersion features :ABS powder adhesion strength is very poor, the thickness of 250-300 microns, strong corrosion resistance.

Eye wash station|safety shower|eyewash and shower station

Eye wash station|safety shower|eyewash and shower station